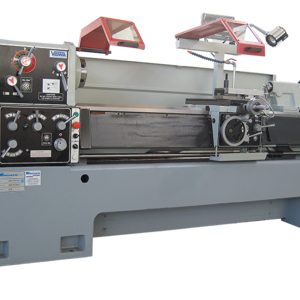

Why should I replace my manual lathe with a CNC lathe like the WDE 500 Plus?

The advantages of a CNC controlled machine

- automated production increases the precision of the workpieces

- Productivity increases, among other things through less downtime due to retooling, reduction of errors with a possible simulation

- the quality and thus the customer satisfaction of your customers increases due to a repeatability of the machining results

- greater flexibility in programming various machining operations enables you to meet a wide range of customer requirements and thus increase your customer base, for example, technology cycles such as threads and fits are supported by the control system

- lower tool costs, as the control and drive minimise the load during machining

- Flexibility and more efficient working through external storage and reading in of programs and CAD data

- energy efficiency through higher productivity

- through energy-efficient working and/or digital measures Possibility of federal or state subsidies

- higher safety standards: Safety precautions are higher with CNC lathes (CNC milling machines, grinding machines) than with manual lathes because they have a full enclosure.

- environmental protection and standards: Due to the full enclosure and containers for oils or chip boxes, standards are met in the handling of waste materials requiring monitoring.

- Higher employee motivation: the digitalised process increases employee satisfaction and motivation with more efficient, high-quality results.

Can I use my existing tools and clamping devices with the CNC lathe?

In most cases, you can continue to use your existing tools and clamping devices.

However, some adjustments or additions may be required to make them compatible with the CNC lathe.

We will be happy to advise you on the possibilities of using existing tools or clamping devices.

Can I transfer my existing programmes directly from the manual lathe to the CNC lathe?

No, the programs for the manual lathe are not compatible with a CNC lathe.

The CNC lathe uses a different type of programming, usually G-code (like the Siemens 828 D Shopturn control or the Fanuc 35i control ) or other specific CNC programming languages.

How long does it take to replace my manual lathe with the CNC lathe?

The exact time required depends on various factors, such as

- the size and complexity of the parts to be machined

- the availability of training for your employees (we support you and offer training)

- the necessary adjustments to your workshop.

Benefit from our many years of experience and let the expert advise you on this and give you a realistic estimate.

Are there certain requirements for the workshop to install the CNC lathe?

Yes, a CNC lathe usually requires:

- a stable power supply

- sufficient space for the machine and, if necessary, for the automated loading system,

- adequate safety precautions (a CNC machine has a higher safety standard than a conventional one due to a full enclosure).

Our consulting team will inform you in detail on request.

What are the maintenance costs for a CNC lathe compared to a manual lathe?

Maintenance costs can vary depending on the model.

Generally speaking, the maintenance costs for a CNC lathe tend to be higher than for a manual lathe.

This is because

- CNC lathes have complex electronic components

- and precise mechanics that require regular maintenance and occasional repairs. We are on hand with our service team to offer advice and assistance.

It is advisable to discuss the maintenance costs with our consultants in advance and to agree on a maintenance schedule.

After all, proactive maintenance keeps the CNC machine free of failures in the long term.

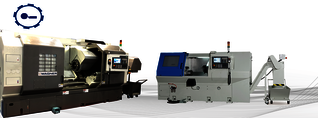

What specific advantages does the WDE 500 Plus offer over the WDR 255 from Maschinen Wagner?

The WDE 500 Plus is a CNC lathe that offers a wide range of advanced features, such as

- a CNC control with a user-friendly operator interface

- automatic tool change

- better precision through accurate positioning

- a wider range of machining operations

How will I be supported during the installation and commissioning of the CNC lathe from Maschinen Wagner ?

In addition to training courses and a complete commissioning and machine handover, we also offer you on-site support from our service technicians throughout the sales area.

Ask us about our support services!

How do I calculate whether a new machine purchase is worthwhile?

The calculation of whether a new machine purchase is worthwhile can be complex and depends on various factors.

As a rule of thumb, you can assume that a CNC lathe with the same quality output will cost less than €20,000 more than a conventional machine.

Here are some steps that can help you in your evaluation:

1. the basis: cost of the possible new acquisition:

- Determine the price of the new machine, including any additional costs such as shipping, installation and training.

2. compare operating costs:

- Establish the operating costs of the new CNC machine, such as energy consumption, maintenance scheduling, spare parts, if applicable, training for your employees.

- Compare these costs with the current operating costs of your old conventional machine.

3. productivity increase?

Estimate the potential increase in productivity from the new machine.

Factors are:

- higher output

- faster machining times

- improved, consistent quality / achievement of customer quality requirements

- Reduced downtime / maintenance

- Customer acquisition through larger machining portfolio

Consider how this could impact your operation and profits.

4. cost savings:

Investigate possible cost savings that could result from using the new machine. These could be, for example:

- a reduction in scrap

- reduced labour hours

- less downtime due to maintenance

5. depreciation and lifetime

How long do you think the old machine will be able to be used? What is the depreciation on this machine?

In addition to the current machine, you should also consider the depreciation of the new CNC machine over its expected lifetime.

CNC use: An investment in the entrepreneurial future?

Investing in a CNC machine can bring the following optimisations:

Automation and efficiency: The use of a CNC lathe enables automated production, reduces manual labour and shortens production times. This leads to more efficient production and higher precision of the manufactured parts.

Flexibility and adaptability: CNC lathes can be programmed for many more and varied machining tasks, allowing them to adapt quickly to changing production requirements - a major advantage in a dynamic market environment.

Increased productivity: You can increase production capacity and reduce lead times by using a CNC lathe. Continuous machining and the ability to operate outside of regular working hours allow for higher productivity with less manpower and increased competitiveness.

Maintenance and reliability: New CNC lathes are more reliable and require less maintenance than older conventional machines. This leads to higher machine availability and reduces downtime, which improves production efficiency and customer satisfaction.

Our goal is to create and improve sustainable business relationships- This also means we want to plan with you for the future. Contact us, we will be happy to advise you.