Stock machines - immediately available

FROM THE SIMPLE ENTRY-LEVEL MODEL TO THE COMPLEX CNC MACHINE...

our current stock list provides you with an overview of our range of products available at short notice. On 4,000 m2 of exhibition space, you can choose from conventional machine tools, CNC lathes (flat bed and inclined bed), CNC milling machines, surface and cylindrical grinding machines to CNC machining centres.

With the Trennjaeger brand, we set a standard in the field of circular saws, band saws and cut-off saws. All under one roof with us in Renchen.

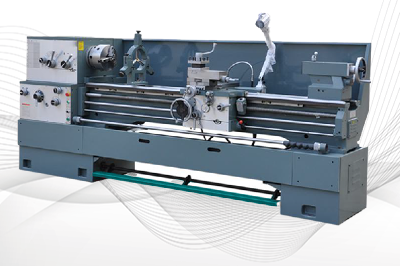

Conventional turning lathe DLC 180B

The proven and solid universal lathe is ideal for the medium demand in mechanical engineering companies and metal workshops. Easy to learn and safe to operate - with a 3-axis position display - will convince you even in training companies.

Digital position display in 3-axes

180 mm Centre height

1000 mm centre distance

-> details

Lathe WDE 500

The WDE 500 is a cycle CNC lathe with automatic gear change in 3 steps. Operating comfort is ensured by the ergonomic arrangement of the 2 electronic handwheels with joystick and rapid traverse via control buttons. Ideal for machining standard parts. This flat-bed lathe also differs from the WDE 360 in the key data:

500 mm turning diameter

Speed of 2200 rpm

8-fold revolver

-> details

Lathe WDE 360

The manually operated CNC lathe WDE 360 is ideal for the production of individual parts and small series. The semi-automatic cycle-controlled lathe is easy to operate and with its numerous options for tool holder system and tool turret it is an optimal flat-bed lathe for economical use. Also available with CNC programming.

Flatbed lathe with turning diameter of 360 mm

ideal for standard workpieces

-> details

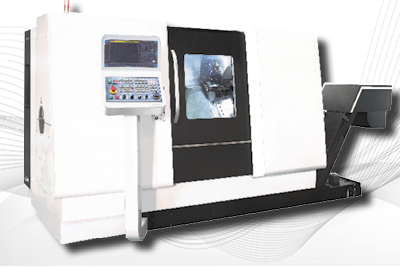

Lathe WDS 680 A/Y

CNC inclined bed lathe with Siemens 828 D control with spindle and feed motors from Siemens. Includes a 12-station turret for driven tools, maximum speed 4,500 rpm.

Automatic central lubrication

45 degree inclined bed

Max. Swing diameter 680 mm

Spindle speed 3,000/4,000 rpm

-> Details

Manual turning lathe DLC 230

The latest version of the DLC series: universally applicable and robust in handling; with hardened and ground bed guides, complete coolant system and central lubrication. Ideal for stationary machining.

3-axis digital display

230 mm centre height

Available with 1.000/ resp. 1500 mm centre distance

-> details

WDE 500 Plus lathe

Sturdy construction - fast, precise and simple programming. This cycle lathe features a Siemens control with linear guidance in X and Z axis. Due to the proven operation in ShopTurn on a user-friendly colour display, your individual and series production is easy.

Control Siemens 828 B-T

1.500 mm max. centre distance

500 mm max. turning diameter over bed

-> details

USED MACHINE!

Lathe WDR 340 G x 3.000

EQUIPMENT of the used machine: centre height 340 mm / swing over bed 680 mm / swing over cross slide 440 mm / centre distance 3000 mm / spindle bore 105 mm (option 155 mm)

Rapid traverse in X- and Z-axis

Fixed steady rest/ travelling steady rest

Conventional turning lathe WDR 255 x 1.500

With this conventional lathe you can make a lot out of little. With a centre distance of 1,500 mm, long workpieces are no problem for this sliding headstock lathe. The compact design proves its worth especially with large workpieces.

Speed range: 36-1500 rpm

fixed stops

Sturdy cast construction with 45 degree inclined bed. The machine is characterised by good accessibility with a large spindle bore at high speed.

Tailstock stroke over the entire length

Integrated chip conveyor

-> Details

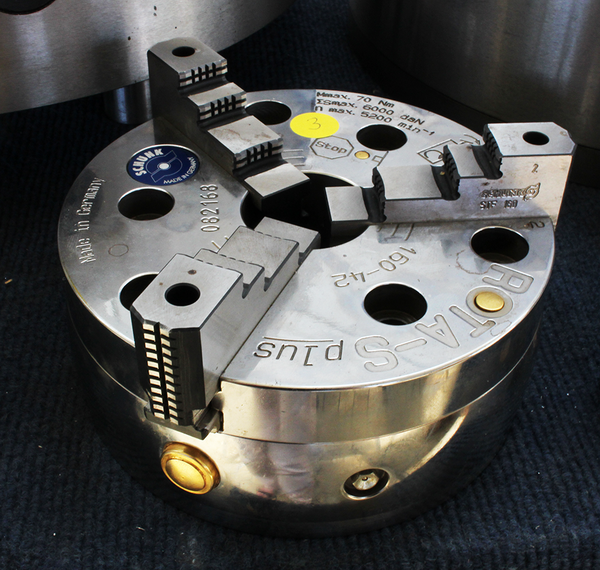

USED MACHINE!

Lathe WDR 1200 G x 2000

EQUIPMENT of the used machine: centre height: 600 mm/ circulation-Ø over bed 1200 mm/ circulation-Ø in the bend: 1700 mm/ circulation-Ø over cross slide: 830 mm

3-axis digital display

3-jaw chuck diameter 635 mm

Quick-change toolholder Multifix type: D1

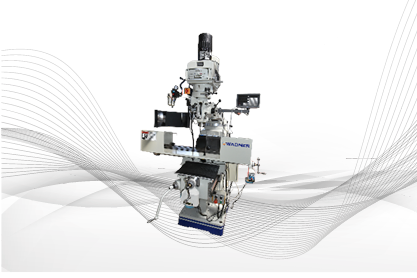

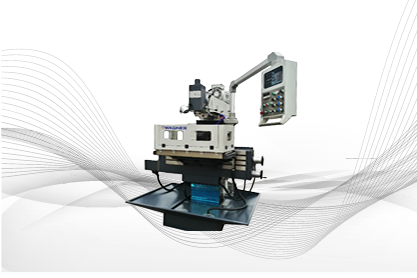

Conventional milling machine FCD 400 / 500 / 600

Easy to use, versatile - this conventional milling machine is a precision tool with horizontal and vertical milling device for use in mechanical engineering and metalworking. The 3-axis digital display with swivel arm offers best operability.

Manual angle table

Main spindle and axle drive infinitely variable

Swivelling vertical milling head

-> details

Conventional milling machine MFC 1270

The console milling machine with swivel and tilt head is popular for machining small to medium-sized workpieces. Stable, robust and known as a multi-purpose milling machine, it is ready for universal use. With digital display.

Traverse paths: longitudinal: 680 mm, transverse: 400 mm

infinitely variable adjustment of the number of spindles

Vertical milling head with powerful spindle motor, the head can be swivelled to the left/right and tilted forwards/backwards

-> details

CNC milling machine FCQ 1370 x 320

This universal milling machine with cross slide impresses by its versatile use. Due to the automatic feed in all 3 axes and the manual operation of the cross slide, small series productions can easily be done by hand.

Universal vertical milling head swivelling in two planes

Separate horizontal spindle

Rapid traverse in the X, Y and Z axes

-> details

DRILLING

DRILLING

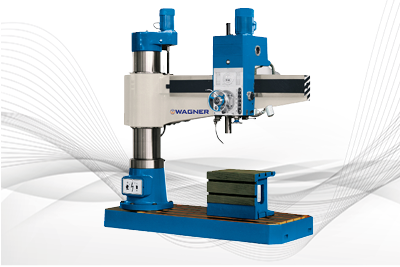

Radial drilling machine PRC 50

Drilling with high performance and simple operation, this and much more is offered by the radial-arm drilling machines.

Drilling machines of the PRC series. They are very robustly built and well thought out down to the last detail.

drilling capacity in steel: 50 mm

Dice table L x W: 500 x 650 mm

Column drilling machine WSB 40 R

The continuously adjustable industrial radial drilling machine has a speed range of 65 - 540

rpm up to 245 - 2,000 rpm With a strong column of 115mm diameter it is universally applicable and space-saving in use.

• 3 automatic feeds, 0.2 / 0.1 / 0.05 mm/rev

• Switch for right-left rotation

• Switch for automatic reversal for threading

GRINDING

GRINDING

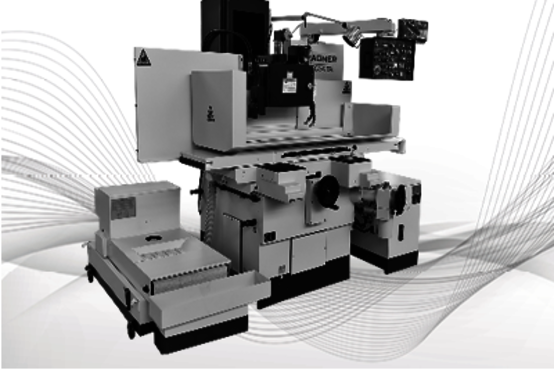

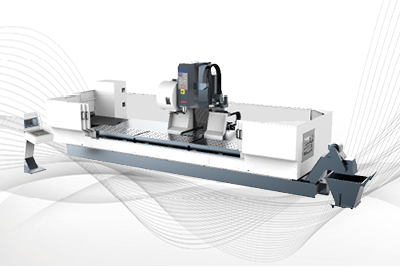

CNC Machining Center WMC 1100

Vertical milling in a class of its own. Especially suitable for your projects in the field of heavy machining.

Linear guided vertical machining centers

cross table, C - design

CNC machining center WMC 1100 dynamic

High performance in heavy-duty machining - this machining centre provides the solution for all jobs with high demands.

A large transverse path and small distance between the table and the housing guarantee fast loading. Available with SIEMENS 828 D, HAIDENHAIN iTNC620 or FANUC OiMB controls.

Spindle: Up to 12,000 rpm

24 double arm changer

Traverse paths: 1100x650x600 mm

-> details

CNC drilling and milling machine BFM 580

CNC drilling and milling in one - with the robust entry-level model you can machine large parts very economically. Especially the automatic lubrication system for moving parts and the chain chip conveyor with gooseneck make this drilling and milling solution a top choice. Optionally with Fanuc or Siemens control.

Spindle SK 40, 10,000 rpm

Double arm tool changer 24 positions

Full enclosure open at the top for crane loading

-> details

Vertical band saw Trennjaeger KV 40

The CNC circular saw for industry and workshop impresses with a strongly dimensioned machine body and a solid cast iron table. The infinitely variable speed stages are designed in the ranges 15-55 m/min and 96-390m/min.

cutting width: 410 mm

2 castors

-> details

Vertical band saw Trennjaeger KV 50

The CNC circular saw for industry and workshop impresses with a strongly dimensioned machine body and a solid cast iron table. The infinitely variable speed stages are designed in the ranges 15-55 m/min and 96-390m/min.

cutting width: 520 mm

2 castors

-> details

Band sawing machine Trennjaeger horizontal TEBA 330 DG/DGHA

Universally applicable, large cutting range - this double mitre saw cuts profile steels, tubes and solid metal material precisely and efficiently. The metal band saw becomes an all-rounder due to the adjustability of the mitre cuts between 90° and 30° - with simultaneous user-friendliness. The manual version is operated by hand; can also be used for semi-automatic sawing.

Stepless cutting speed 15-90 m/min

Saw blade guide with carbide plates on both sides

saw band dimensions: 3150x27x0,9 mm

-> details

Band sawing machine Trennjaeger TEBA 260 DG/ DGHA

This horizontal industrial band saw provides an uninterrupted cut due to its saw band guide with carbide plates on both sides.

The TEBA 260 DG meets the high demands on drive and saw blade in daily operation by a robust design.

Mitre on both sides with scale

Clamping by sliding vice left and right

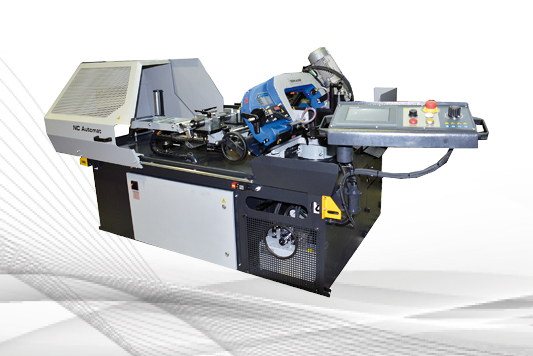

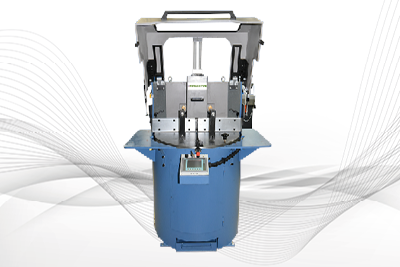

Band sawing machine Trennjaeger TEBA 300 ANC

This fully automatic CNC band saw is optimally equipped to meet a wide range of processing requirements. With 60 programs - freely selectable and linkable - you are sure to find what you are looking for via the Schneider Elektrik control system.

Fixed vice automatic manual presetting

Mitre with front clamping lever

Vertical band saw Trennjaeger KV 60

The dynamic band saw impresses with a work table that can be tilted 15° to all sides. Even larger workpieces are no problem: 3 rollers and a cutting width of 620mm provide the right tool for your processing.

integrated chip brush

speed stages via gear wheel transmission (oil bath run-through)

-> Details

Grating high-speed circular saw Trennjaeger UNI 9 / Automat series

Feed via stepless motor and chain

Speed 3000 rpm with Proma solid steel blade 560 mm

Fuse protection 25kW / 37kW at least 100/200 amps

Performance braking system

Vertical clamping system

- > details

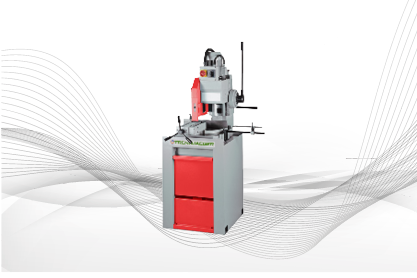

Circular sawing machine Trennjaeger S 315

If your production requires flexible and universal cuts in steel and non-ferrous metals, the classic from Trennjaeger is your choice.

-> details

Vertical circular saw Trennjaeger VCT 400 HA

The VCT 400 HA sawing machine is specially designed for fast cutting up to a saw band size of 400 mm. You get a stable and durable semi-automatic machine.

With this gear, the vertical saw is suitable for stainless steels, acid-resistant or solid materials and thick-walled material.

Motor with 2 speeds

Electric panel with individual functions

Chip drawer integrated and additionally separate

-> details

Cold circular saw Trennjaeger TUS 470 HA

The linear guided underfloor circular saw is ideal for straight and mitre cuts. It can be tilted on both sides from 90° to 45° to 30°. In addition, the version includes an adjustable vertical vice on both sides.

Digital display for swivel angle

Infinitely variable mitre

Stepless cutting speed

-> details

Circular sawing machine Trennjaeger WAK TL 350 HA

Stable, safe and versatile - this semi-automatic sawing machine is ideal for fast and precise cutting of profiles made of aluminium and non-ferrous metals. The mitre cut on both sides can be made by infinitely variable mitre cut adjustment from 20°-90°-0°.

Saw blade Ø, mm 350

Cutting speed: 3,000 rpm.

Control via function keys, with direct drive