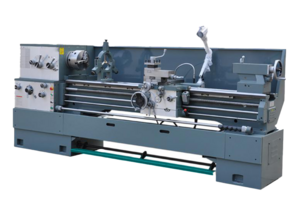

DLC 230

Universal application and robust handling; with hardened and ground bed guides, complete coolant system and central lubrication. Ideal for standard machining.

- Standard parts machining

- 3-axis digital display

- Flatbed

DLC 330

Universal lathe with digital readout for 3-axis, fully mounted

- Standard parts machining

- 3-axis digital display

- Flatbed

WDR 205

Hochwertige Leit- und Zug-Drehmaschine: H-Bauform; optional stufenlose Drehzahl

- Compact design, heavy base frame

- Max. Speed up to 2,700 rpm.

- Motor spindle brake

WDR 255

With a centre width of 1500 mm, long workpieces are no problem for this long-turning machine.

- Compact design, heavy base frame

- Max. Speed up to 2,700 rpm.

- Motor spindle brake

WDS 570 A x 500 /850

Sturdy cast construction with 45 degree inclined bed. The machine is characterised by good accessibility with a large spindle bore at high speed.

- Driven tools

- 45 degree sloping bed

- Good accessibility

WDS 680 A/Y x 1050/ 1600/ 2350

CNC inclined bed lathe with Siemens 828 D control. Includes a 12-station turret for driven tools, maximum speed 4,500 rpm.

- Driven tools

- Y-axis

- Counter spindle (option)

WDE 400

The WDE 400 is a cycle CNC lathe with automatic gear shifting in 3 stages.

- Flatbed lathes

- Standard parts machining

- Solid cast iron beds on feet

WBK 1600

- Heavily ribbed vertical stand, resulting in low-vibration spindle operation

- Digital position indicator

- Control panel with ergonomically arranged function buttons incl. swivel arm

FCD 500

The FCD 500 is a precision tool with a horizontal and vertical milling unit. The 3-axis digital display with swivel arm offers optimum operability.

- Precision milling machine

- Horizontal and vertical milling device

- Horizontalis removable for vertical machining

FCD 600

The FCD 600 is a precision tool with a horizontal and vertical milling unit. The 3-axis digital display with swivel arm offers optimum operability.

- Precision milling machine

- Horizontal and vertical milling device

- Horizontalis removable for vertical machining

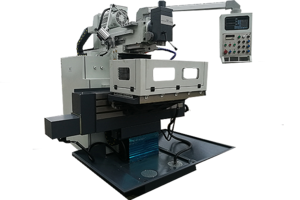

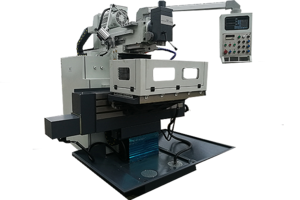

FCQ 1370

This universal milling machine with cross slide impresses with its versatility.

Universal vertical milling head swivelling in two planes Separate horizontal spindle Rapid traverse in the X, Y and Z axes

- Universal vertical milling head swivels in two planes

- 3-axis digital position indicator

- Automatic feed in all 3 axes

FCQ 1600

- Universal vertical milling head swivels in two planes

- 3-axis digital position indicator

- Automatic feed in all 3 axes

WMC 800 L

- Traverse path X: 800 mm

- Linear guides in all 3 axes

- Work area: 800 x 500 x 550 mm

- ECO version

- Linear guided vertical machining centers

- Cross table, C-design

WMC 1100 Dynamic Edition

Vertical milling machines in a class of their own. Particularly suitable for your heavy-duty machining projects.

- Flat-guided, vertical machining centers

- Vibration-damped properties

- Cross travel from: 650 - 800 mm

BFM 580 CNC x 3000

CNC drilling and milling in one - with this robust entry-level model you can machine large parts very economically. Optionally with Fanuc or Siemens control.

Spindle SK 40, 10,000 rpm Double-arm tool changer 24 positions Full enclosure open at the top for crane loading

- Tapping without compensating chuck

- Indicator light and automatic switch-off

- Machine light

WMC 5A 630

- Suitable for automation

- Motor spindle with max. 18,000 rpm.

- Crane loading possible

WMC 1300 C

- Flat-guided, vertical machining centers

- Vibration-damped properties

- Cross travel from: 650 - 800 mm

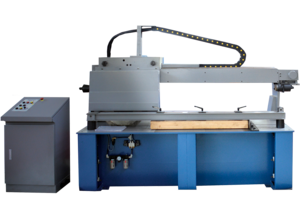

FSG 3A-1224

- Premium surface grinding machines

- Cross table

- Longitudinal travel from: 450 - 610 mm

FSG AD IV 1224

Highly efficient with infinitely variable cutting speed as standard. With maximum sanding length of 610 mm. Max. sanding width 305 mm.

- Precision spindle with 4 angular contact ball bearings

- Stepless spindle speed

- Vertical via AC servo motor CNC axis

FSG AD IV 1632

- Precision spindle with 4 angular contact ball bearings

- Stepless spindle speed

- Vertical via AC servo motor CNC axis

FSG AD IV 1640

Highly efficient with infinitely variable cutting speed as standard. Spindle motor AC servo Stepless spindle speed Vertical via AC servo motor CNC axis.

- Precision spindle with 4 angular contact ball bearings

- Stepless spindle speed

- Vertical via AC servo motor CNC axis

PRC 50

Bohren mit hoher Leistungsfähigkeit bei einfacher Bedienung, dies und vieles mehr bieten Ihnen die Radial-

Bohrmaschinen der Baureihe PRC.

- Drilling capacities in steel from: 50 - 100 mm

- Preselection switch for: Speed and feed rate

- All 3 axles can be clamped separately

PRC 50 Digi (mit Aktiv-Digitalanzeige)

Drilling with high performance and simple operation - this and much more is offered by the radial drilling machines in the PRC series.

Drilling capacity in steel: 50 mm Cube table L x W: 500 x 650 mm

- Drilling capacities in steel from: 50 - 100 mm

- Preselection switch for: Speed and feed rate

- All 3 axles can be clamped separately

PRC 60

- Drilling capacities in steel from: 50 - 100 mm

- Preselection switch for: Speed and feed rate

- All 3 axles can be clamped separately

WSB 40 R

The infinitely variable industrial radial drilling machine has a speed range from 65 - 540 rpm to 245 - 2,000 rpm.

rpm to 245 - 2,000 rpm.

- 3 automatic feeds

- Switch for automatic reversal for thread cutting

- Strong column 115 mm diameter

WSB 50 R Digital

- 3 automatic feeds

- Switch for automatic reversal for thread cutting

- Strong column 115 mm diameter

S 315 / S 315 HA

If your production requires flexible and universal cuts in steel and non-ferrous metals, the classic from Trennjaeger is your choice.

- Motor 2 speeds

- Cooling/flush lubrication system with pump

- Strongly dimensioned, powerful worm gearbox

S 350 / S 350 HA

- Motor 2 speeds

- Cooling/flush lubrication system with pump

- Strongly dimensioned, powerful worm gearbox

VCT 400 HA

The VCT 400 HA sawing machine is specially designed for high-speed cutting up to a band saw blade dimension of 400 mm. With this gearbox, the vertical saw is suitable for stainless steels, acid-resistant or solid materials and thick-walled material.

- Motor 2 speeds

- Cooling/flush lubrication system with pump

- Strongly dimensioned, powerful spur gearbox

SPA 160 HM

- Blow-off and brushing system

- Minimum lubrication system System

- Residual piece and good part sorting

WAK-TL-450-CNC

- Omron control unit with color touch display

- Material pusher feed with 6,000 mm length

- Pneumatic material clamping system 2-fold horizontal and 1-fold vertical

UNI 9 - 25 - 1550

- Feed via stepless motor and chain

- Performance braking system

- Vertical clamping system

WAK 420 HA

- saw blade 420 mm

- cutting range: max. height 145 mm and max. width 330 mm

- Stepless miter cut adjustment 15° - 90° - 15°

- Safety two-hand operation via push-button

- Electrically secured safety hood

WAK 700 HA

- Stepless miter cut adjustment 15° - 90° - 15°

- Safety two-hand operation via push-button

- Electrically secured safety hood

TUS 425 HA

Circular saw for burr-free cold sawing of profiles, panels and square and round material. For stepless, double-sided straight and mitre cuts.

- for burr-free cold sawing

- 4-axis spur gearbox

- Hydraulic system with overload protection

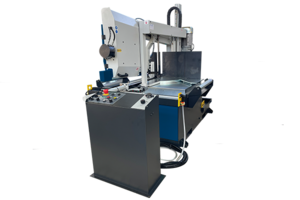

TEBA 260 DG

This horizontal industrial band saw delivers uninterrupted cutting.

The TEBA 260 DG meets the high demands placed on the drive and saw blade in daily operation with its robust design.

- Robust and solid design

- Cast saw frame

- Cast iron machine table

TEBA 300 DGHA

- Robust and solid design

- Control panel with individual function buttons

- Infinitely variable cutting speed 15-90 m/min

TEBA 510 DGHA-L

- Pendulum control panel with function buttons and digital display

- Infinitely variable cutting speed

- Infinitely variable feed rate

- Double linear guide with closed frame

- Pendant control panel with function buttons and digital display

- Infinitely variable cutting speed

KV-40

The CNC circular saw for industry and workshops impresses with a large machine body and a solid cast iron table.

- KV 40/50 twin castors

- KV 60/100 Three castors

- Doors for saw blade change

KV-50

The CNC circular saw for industry and workshops impresses with a large machine body and a solid cast iron table.

- KV 40/50 twin castors

- KV 60/100 Three castors

- Doors for saw blade change

KV-60

The dynamic automatic circular saw impresses with a work table that can be tilted 15° to all sides.

- KV 40/50 twin castors

- KV 60/100 Three castors

- Doors for saw blade change

We are there for you -

for the life of the machine!

Do you have questions about our machines, service or spare parts?

We are happy to advise you. Promptly and without obligation.